This paper mainly introduces the function and related knowledge of PCB factory, including the processing flow, workflow, equipment and technology, market and trend of PCB factory. Through the discussion of these contents, readers can have a deeper understanding of the relevant knowledge and industry trends of circuit board processing plants.So we can draw a preliminary conclusion, pcb assembly manufacturer It is helpful to the needs of the industry market and social development. https://intechcircuit.com/

First, the circuit board processing flow

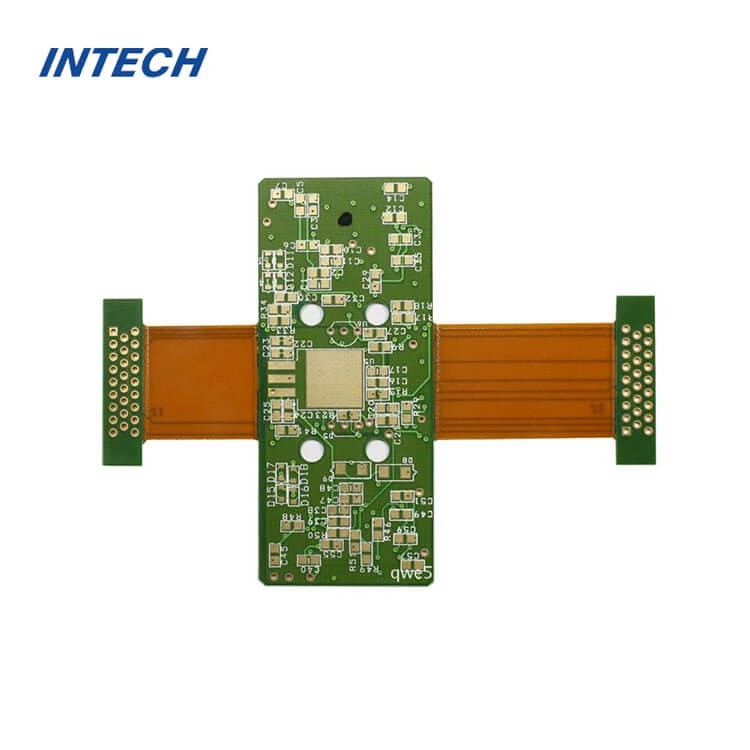

First of all, let’s talk about the circuit board processing flow including design, plate making, blanking, drilling, copper plating, cutting, press-fitting, inspection and other steps. Design and plate making are the preparatory work of circuit board processing, blanking and drilling are the core processes of circuit board processing, while copper plating, cutting, press-fitting and inspection are the follow-up links of circuit board processing.

Second, the circuit board processing factory workflow

The workflow of circuit board processing factory includes receiving orders, making samples, confirming designs, mass production, inspection, packaging and delivery. In every process of circuit board processing, the circuit board processing factory needs to strictly abide by the relevant technical requirements and quality standards to ensure that the manufactured circuit boards meet the requirements of customers and industry standards.

Third, the equipment and technology of the circuit board processing factory

Circuit board processing plants need to use a variety of technologies and equipment, including CNC milling machine, etching machine, spraying line, cooler, UV curing machine, automation equipment and so on. In addition, the circuit board processing factory also needs to have certain technical strength and quality assurance ability to ensure that the produced circuit boards can run stably and meet the needs of customers.

Fourth, the market and trend of circuit board processing plants

The market of circuit board processing factory mainly includes communication, computer, consumer appliances, automotive electronics, medical electronics and other industries. With the continuous development of Internet of Things, 5G communication, artificial intelligence and other technologies, the market space and demand of circuit board processing industry will be broader. At the same time, PCB processing plants are also facing challenges and opportunities such as technological upgrading, environmental pressure and international competition.

Circuit board factory is a very important manufacturing enterprise, and the circuit boards it produces are an indispensable part of modern electronic equipment. By studying the knowledge of circuit board processing flow, work flow of circuit board processing plant, equipment and technology of circuit board processing plant, market and trend, we can better understand the function and work flow of circuit board processing plant, and provide reference and guidance for related enterprises and employees.